Current Focus

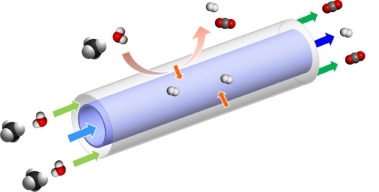

Membrane and membrane reactor

A membrane reactor integrates chemical reaction and selective membrane separation in a single unit, offering enhanced process efficiency. The membrane selectively allows certain components to pass through while retaining others, facilitating continuous product removal and improving reaction rates. By maintaining optimal conditions and efficient mass transfer, membrane reactors intensify reactions, leading to higher yields and reduced energy consumption. They also enhance product purity by suppressing byproduct formation and minimizing side reactions. Additionally, membrane reactors simplify process design and operation, reducing equipment footprint and capital costs. Their versatility finds applications across industries, including petrochemicals, pharmaceuticals, and environmental remediation, offering significant advantages over traditional separation and reaction systems.

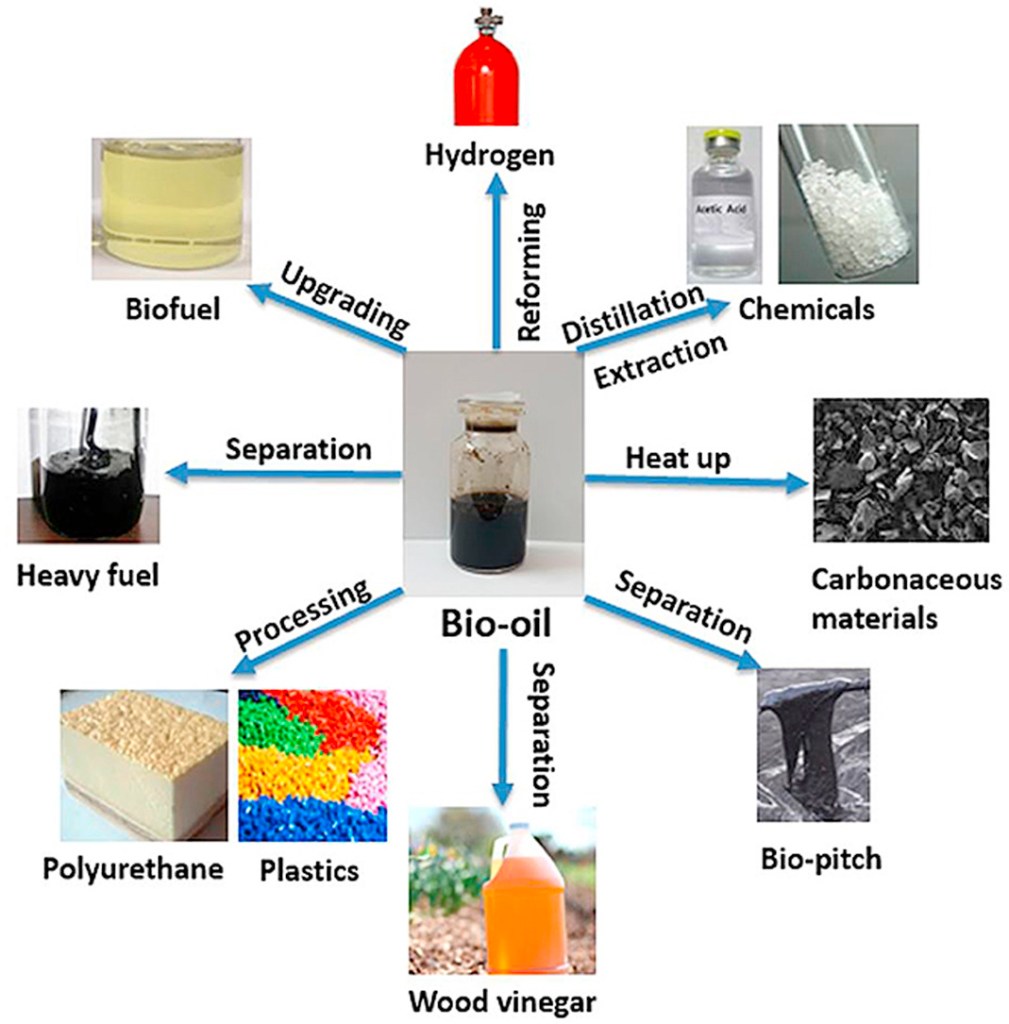

Bio-oil upgrade to chemicals and fuel

Researching bio-oil stabilization for fuel and chemical applications is a promising endeavor with significant implications for renewable energy and sustainable chemistry. Bio-oil, derived from biomass through processes like pyrolysis, contains a complex mixture of organic compounds that can be upgraded into valuable products. Stabilizing bio-oil involves addressing challenges such as its high oxygen content, instability, and tendency to degrade over time.

One avenue of research involves developing effective stabilization techniques to enhance the shelf-life and quality of bio-oil. This may include methods such as catalytic upgrading, solvent extraction, hydrotreating, and blending with other fuels or additives. Catalytic processes can help remove oxygen-containing compounds and convert them into more stable hydrocarbons suitable for fuel applications.

Furthermore, exploring the use of bio-oil as a feedstock for chemical synthesis presents opportunities to produce a wide range of valuable chemicals and materials. By refining bio-oil into platform chemicals like phenols, aldehydes, and ketones, it can serve as a renewable alternative to petroleum-based feedstocks in various industries, including pharmaceuticals, plastics, and fine chemicals.

Advancements in bio-oil stabilization and utilization can contribute to reducing greenhouse gas emissions, mitigating reliance on fossil fuels, and promoting a more sustainable bioeconomy. Interdisciplinary research efforts combining expertise in chemistry, engineering, and materials science are essential to address the technical challenges and unlock the full potential of bio-oil as a renewable resource.